Does Your Crank Grinder Need A Checkup?

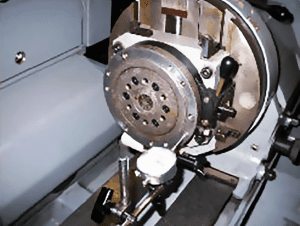

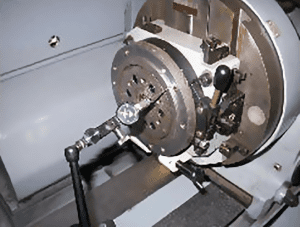

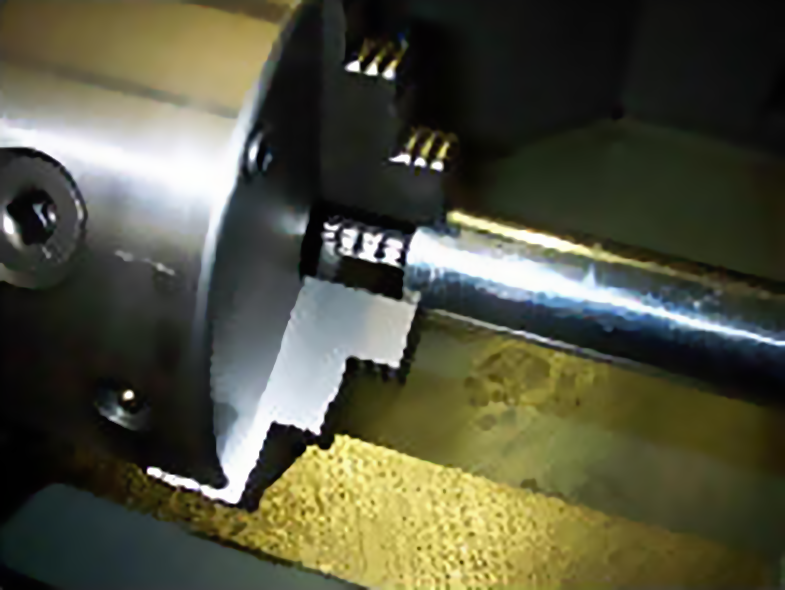

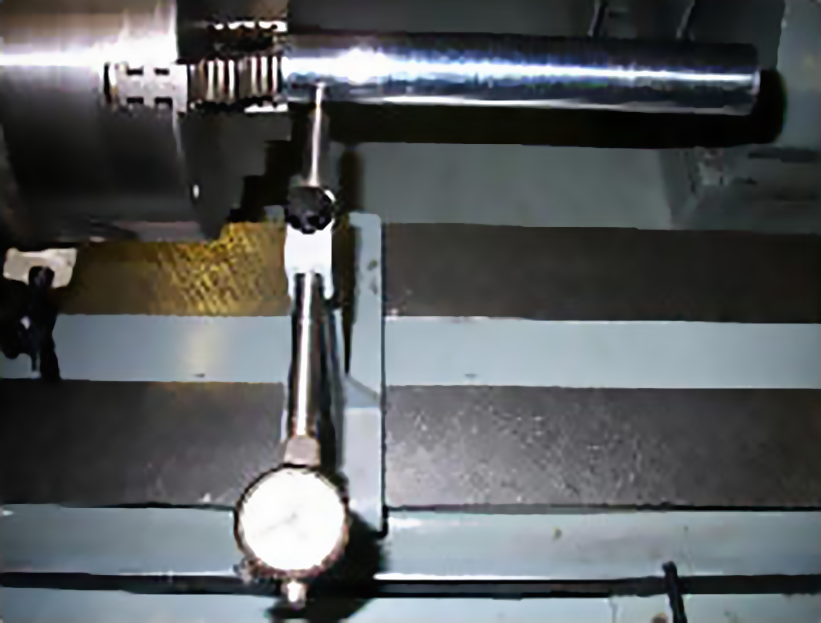

When crankshaft grinders start getting old and not performing like they did when new there are some simple checks that most shops can make to figure out what is wrong. Since most crank grinders have chucks we will concentrate on those machines.

Grinders that only use centers can use the same procedures for “spindle bearing alignment” except the test bars will have to be machined to fit where the centers go in the machine before they can be ground for testing.

It’s a very common assumption to think that out of round grinding is caused by wear in the chucks. While chucks can be a problem, there can be other issues with the grinder. So before you make a sizeable investment in a pair of chucks that you might not need, you can go through some easy checks to see what is really causing your problems.

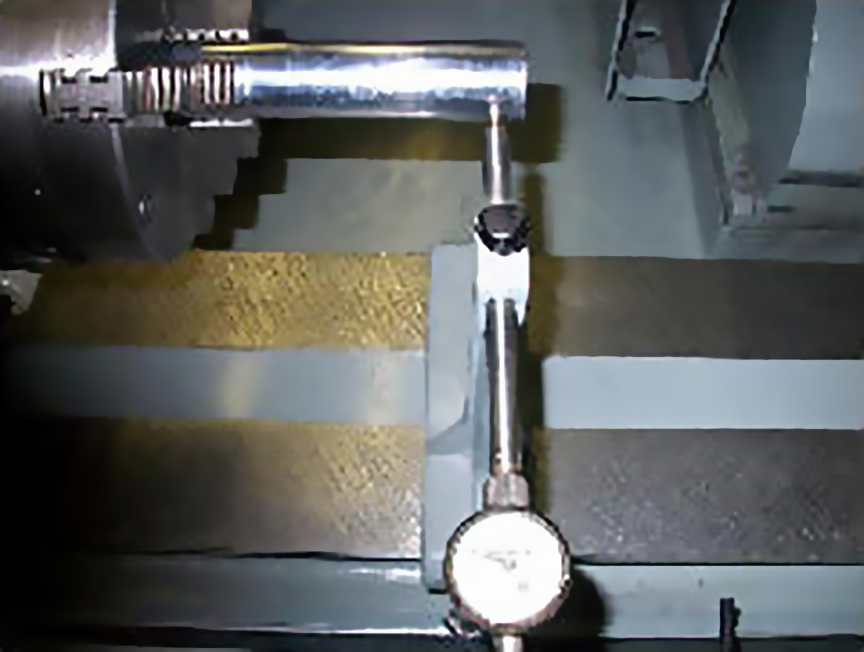

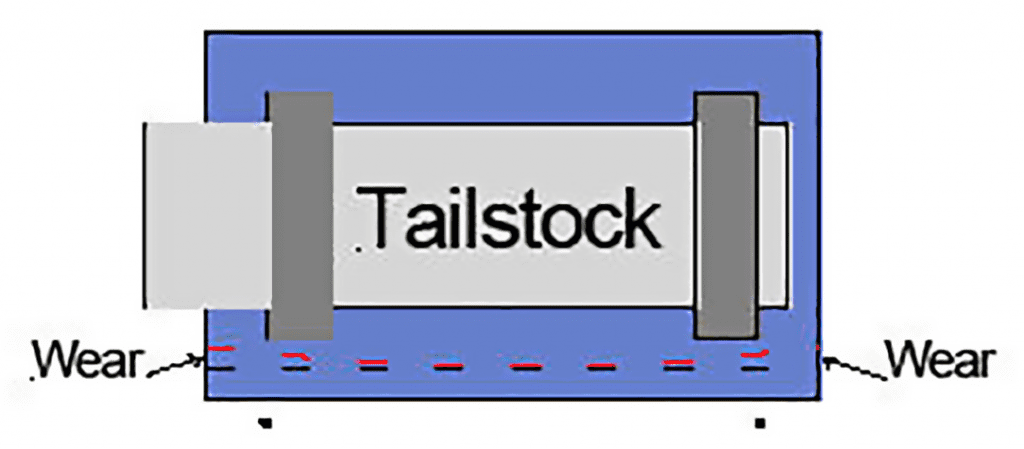

Because you are going to do quite a number of measurements, be certain to write the numbers down. After the checks are complete if you talk to someone that repairs machines and you want to give them an accurate picture of what you discovered. Be certain to clean under the head and tailstock and remove any nicks and burrs from the table before starting!